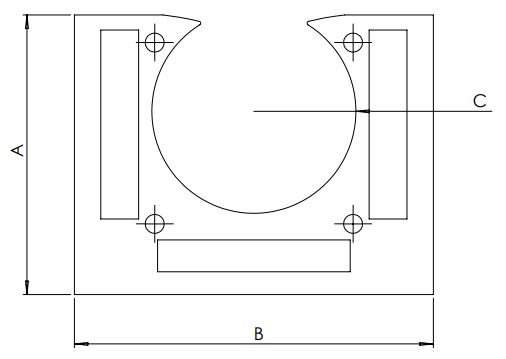

Top Plate

| Dimension | AB12 (mm) | AB18 (mm) |

| A | 74 | 74 |

| B | 95 | 89 |

| C | 22 | 12 |

Bottom Plate

| Dimension | AB12 (mm) | AB18 (mm) |

| A | 74 | 74 |

| B | 95 | 89 |

| C | 22 | 12 |

-

What are Bronze Protector Plates?

Bronze Protector Plates are specialised, durable plates made from high-quality bronze and designed to hold a protective glass shield to protect the glass gauge fitted on the system.

-

What does the AB12 or AB18 Code refer to?

The AB12 and AB18 codes are specifications that indicate the model of boiler gauge mounts that the protector suits. This is originally the Klinger AB12/AB18 model, but it will also fit a wide range of other brands that have a similar design.

-

What applications are Bronze Protector Plates used for?

These plates are primarily used in glass gauge mountings where the gauge glass needs an extra layer of protection from breaking and cracking.

-

What materials are used in the construction of an assembly of the Glass Protector?

The protector is primarily composed of a brass bottom plate, threaded rods, and three panes of protective glass or polycarbonate. The bottom plates and threaded rods are made up of brass. This combination provides both durability and stability, ensuring the water level gauge remains shielded from impact and environmental factors.

-

How does this assembly of glass protectors and plates safeguard the water level gauge?

The unit guards against accidental impacts, debris, and other forms of damage by enclosing the gauge with three protective glass panes and a sturdy brass bottom plate. This helps maintain accurate readings and extend the gauge's service life.

-

How is the glass protector assembled?

The unit arrives disassembled to streamline shipping. To assemble, begin by positioning the brass bottom plate and threading the rods through it. Next, carefully slide the top and bottom pieces into place around the three glass panes. Once aligned, adjust the grub screw and retaining nut at an appropriate angle to secure the unit firmly. If you are still not sure, please watch our video guide.

-

Do I need special tools for assembly and installation?

Basic hand tools, such as screwdrivers and wrenches, are typically sufficient. These tools will help you adjust the threaded rods, tighten the grub screw, and ensure the unit is properly secured. Always follow the manufacturer’s instructions for best results.

-

Can the glass protector be easily transported?

Yes. The glass protector is shipped disassembled to minimise shipping size and reduce potential transit damage. The simple assembly process allows for convenient on-site installation after delivery.

-

How do I ensure that the glass panes and rods are aligned correctly?

Carefully follow the manufacturer’s instructions. Align the glass panes to secure each between the rods and the bottom plate. Ensure each component is parallel and level before tightening the grub screw and retaining nuts.

-

What should I do if the glass protector feels loose after assembly?

Check the tightness of the retaining nut and grub screw. Minor adjustments often resolve any looseness. If issues persist, consult the installation guide or simply contact our customer support team for further assistance.

-

Will the glass protector affect the visibility of the water level gauge?

No. The protective glass panes are designed for clear visibility. They allow operators to easily view and monitor the water level within the gauge without compromising clarity or accuracy.

-

Is regular maintenance required for the glass protector?

Periodically inspect the unit for signs of wear, debris buildup, or loose components. Clean the glass panes as needed with a soft cloth and a suitable cleaning solution. Furthermore, tighten any loose nuts or screws to maintain the protector’s structural integrity.

-

What if my specific installation environment differs from the standard setup?

Always follow the general assembly guidelines. For unique conditions or complicated setups, consult with our customer support team.

-

Where can I purchase replacement parts for the unit?

Replacement parts can be obtained through our authorised distributors or by contacting our customer support team directly. When ordering parts, ensure you have the valve model number and specifications.

-

How can I contact Stead & Baker for further information or technical assistance?

If you need technical assistance, installation help, or have any other questions about this unit, you can contact us via our official website or customer service phone number.

| SKU | GPB |

| Brand | Stead and Baker |

Help other Stead & Baker users shop smarter by writing reviews for products you have purchased.

.JPG)